KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening this week! discover riva, the historic brand that blending technology and tradition, reinventing a contemporary, modern, and unique style for fiberglass yachts between 27 and 164 feet in length.

PRODUCT LIBRARY

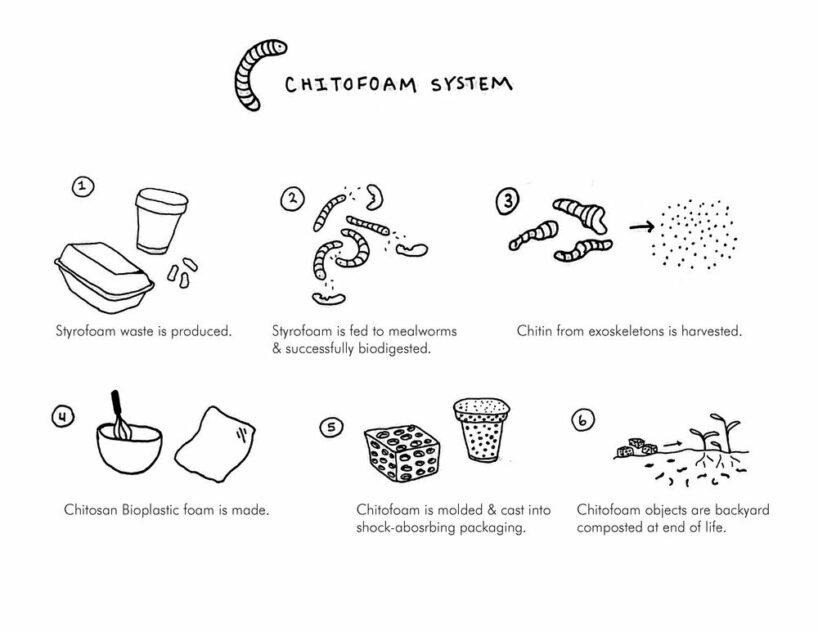

'by osmosis' explores a circular process in which waste generated by one process serves as nourishment for another.

connections: +230

explore the design and architecture of the paris 2024 olympics, as well as the city shows coinciding with the games.

connections: +620

TERRA COSMOS deciphers new desires and expectations of consumers in search of awe-inspiring experiences through a vision of the future.

connections: 2

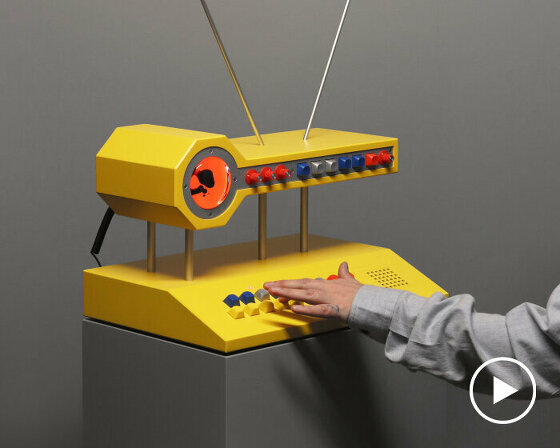

as visitors press the keys, a gooey liquid is brought to life, dancing hypnotically in sync with the chilling tunes.

connections: +250

all images by charlotte böhning and mary lempres of doppelgänger

all images by charlotte böhning and mary lempres of doppelgänger